- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

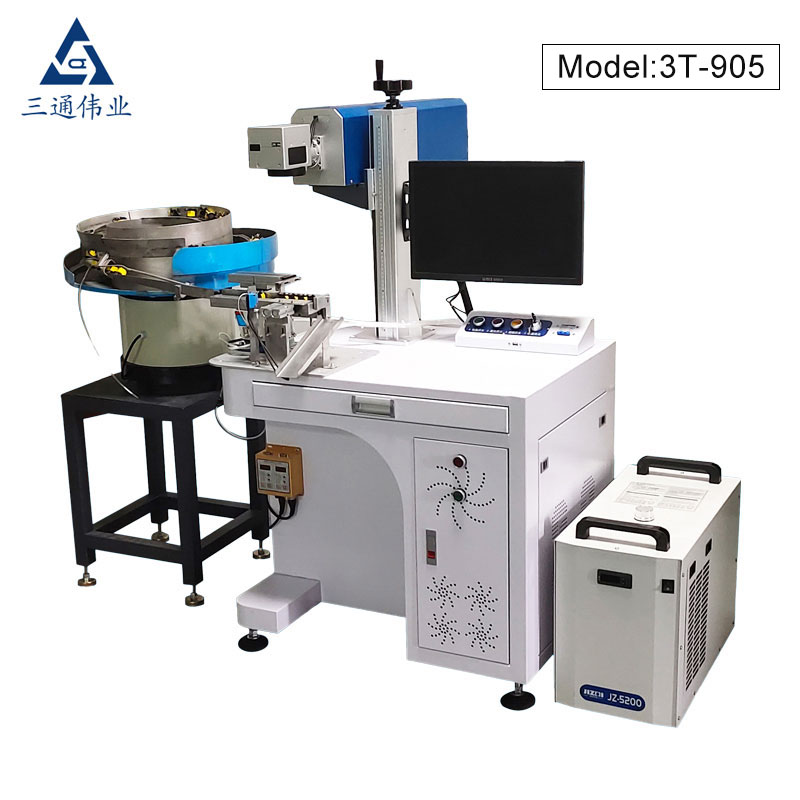

Vibration Disc Cutting And Peeling Paint Machine

Santong Weiye, based in China, stands at the forefront of innovation with its Vibration Disc Cutting and Peeling Paint Machine. As a leading player in the industry, our factory combines state-of-the-art technology with precision engineering to deliver cutting-edge solutions.

Model:3T-906

Send Inquiry

Santong Weiye‘s specialized Vibration Disc Cutting And Peeling Paint Machine showcases our commitment to providing top-notch equipment for various applications, ensuring efficient and precise disc cutting and paint peeling processes. Santong Weiye's Vibration Disc Cutting and Peeling Paint Machine not only exemplifies our dedication to quality but also reflects our role in advancing industrial automation. Trust in Santong Weiye for reliable and high-performance machinery, designed to meet the evolving needs of the global market.

Established in 2014 in the vibrant innovation hub of Shenzhen, Guangdong Province, China, Shenzhen Santong Weiye Technology Co., Ltd. relocated its production facility to Tangxia, Dongguan, in 2019, aligning with the city's burgeoning industrial landscape. With Shenzhen holding the esteemed title of the "Capital of Innovation," our company thrives on its commitment to cutting-edge technology and development.

Boasting a team of skilled technical experts with over 15 years of experience in the fields of winding equipment and laser technology, Shenzhen Santong Weiye Technology Co. Ltd. has emerged as a comprehensive provider of automation solutions. Specializing in the research, development, production, sales, and service of winding machines, laser stripping machines, vibration disc cutting and peeling paint machines, and various non-standard automation equipment, our company has positioned itself as a prominent player in the automation and coil manufacturing sector.

Our product lineup, including the Vibration Disc Cutting And Peeling Paint Machine, and other automation equipment, is renowned for its exceptional quality and competitive pricing. Penetrating the European and U.S. markets, we take pride in delivering reliable solutions to meet diverse industry needs. Shenzhen Santong Weiye Technology Co., Ltd. looks forward to establishing a long-term partnership with your esteemed company, offering innovative automation solutions and ensuring mutual success in the ever-evolving landscape of industrial technology.

3T-907 automatic paint stripper for three-layer insulated wire

Model Features

1. 3T-907 automatic paint stripper for three-layer insulated wire professional three-layer insulated wire stripper can strip 15 to 20 winding transformers at one time with high precision, which can effectively avoid material damage caused by long-term tin dipping and high temperature;

2. 3T-907 automatic paint stripper for three-layer insulated wire is easy to operate, and can easily strip wires with special requirements that are difficult to be completed by traditional processes;

3. 3T-907 three-layer insulated wire automatic paint stripper is completely non mechanical contact processing, which does not produce any mechanical extrusion or mechanical stress on processing materials, and the processing quality is good;

4. 3T-907 three-layer insulated wire automatic paint stripper can precisely control the stripping position, size and depth, with high repeated positioning accuracy and good consistency;

5. 3T-907 automatic paint stripper for three-layer insulated wire, after stripping, the tensile strength of wires of various models and specifications is greater than that of wires after thermal stripper;

6. The inner and outer insulation layers of the conductor shall be free of wire drawing and irregularity after stripping by 3T-907 three-layer insulated wire automatic paint stripper;

7. 3T-907 three layer insulated wire automatic paint stripper has no change in the insulation performance of the wire before and after stripping

Applicable Materials

Most non-metallic materials and some metallic materials. Examples include paper, plastics, films, tin foil, glass, bamboo and wood products, plated metals, electronic components, leather, etc.

Suitable Industries

Three-layer insulated wire stripping, plastic packaging surface marking, tobacco, pharmaceutical, food and beverage, alcohol, health care products, electronics industry, card making, handicrafts, chemical building materials and other industries.

Model Benefits

1. Imported RF metal tube CO2 laser is used, with a service life of 25000 hours, maintenance free, stable performance, and no consumables.

2. Fast marking speed and low marking cost.

3. Marking clear, not wear, engraving and cutting high, environmental protection, energy saving.

4. The software can be compatible with DXF, PLT, AI and other formats.

5. Optional rotary table and all kinds of automation supporting system.

|

Model parameters |

3T-907A |

3T-907B |

3T-907C |

|

laser model/wavelength |

C02/10.64um |

||

|

laser source |

CO2 gas |

||

|

Maximum laser power |

60W |

100W |

120W |

|

Beam quality M |

8 |

||

|

Q-switching frequency |

0-50KHZ |

||

|

marking the smallest character |

0.3mm |

0.3mm |

03mm |

|

The minimum line width of the marker |

0.10mm |

0.15mm |

0.3mm |

|

Marking speed |

250 characters per second |

300 characters, 1 second |

350 characters per second |

|

Repeatability |

0.001mm |

0.002mm |

0.002mm |

|

Engraving range |

140 * 140mm or 175 * 175mm optional |

||

|

exterior dimensions |

980*680*1200mm |

||

|

Overall weight |

200Kg |

||

|

power requirements |

220V/50Hz |

||

|

Cooling method |

Water-cooled |

||

|

Whole machine power |

2KW |

3KW |

5KW |