- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

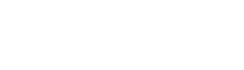

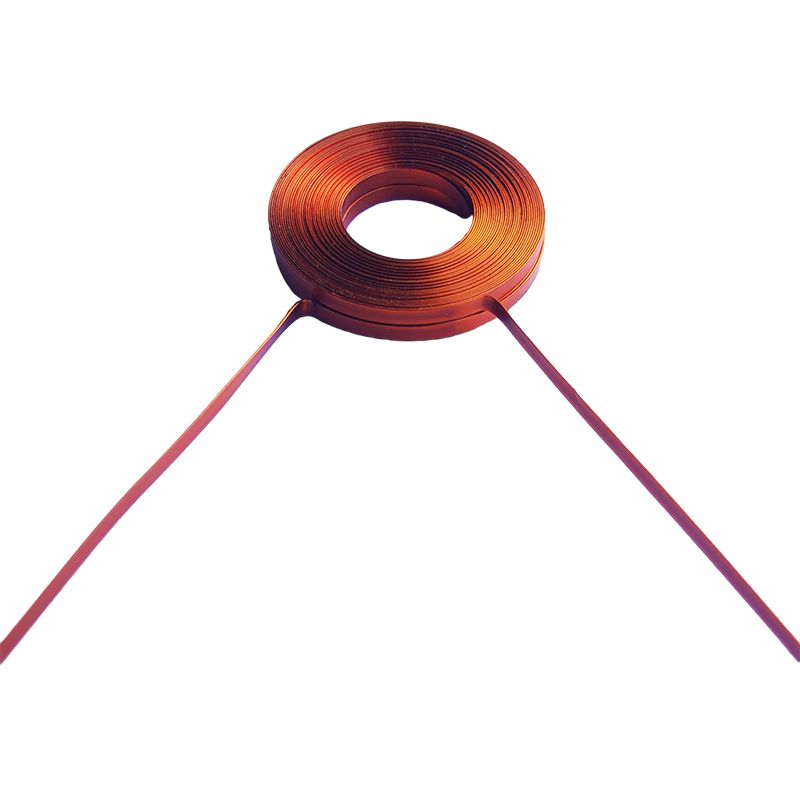

Flat Wire Alpha Coil Winding Machine

Step into the realm of advanced winding technology with Santong Weiye, a trusted name in the industry. Our Flat Wire Alpha Coil Winding Machine sets a new standard in precision and efficiency. Engineered with cutting-edge technology, this machine is designed to meet the demands of modern manufacturing.

Model:3T-809A

Send Inquiry

As suppliers of top-tier automation equipment, Santong Weiye leverages its technical expertise and industry experience to deliver high-quality solutions. The Flat Wire Alpha Coil Winding Machine, a shining example of our capabilities, caters to diverse industrial needs with precision and efficiency. Our dedication to providing advanced machinery aligns seamlessly with the evolving demands of the market.

At Santong Weiye, we envision ourselves not just as manufacturers but as partners in progress, offering innovative solutions that propel industries forward. Join us in exploring the future of automation technology, where our advanced equipment, including the Flat Wire Alpha Coil Winding Machine, sets new standards for reliability and performance.

Five Reasons to Choose Us:

1. Extensive Expertise: With a technical team boasting two decades of hands-on experience in coil winding machines and automation equipment, we bring a wealth of industry knowledge to the table. Our dedicated professionals are committed to delivering top-notch products and services, ensuring our customers derive maximum value from their production processes.

2. Prompt Responsiveness: Our commitment to customer satisfaction is reflected in our 24/7 one-stop service. The sales and technical support team is always ready to address customer needs promptly, guaranteeing the seamless operation of production lines. Quick responses are the cornerstone of our service philosophy.

3. High-Quality Manufacturing: Renowned for producing winding machines of superior quality, performance, and stability, our products have gained recognition from industry leaders such as Huawei, DJI, and BYD. Our equipment not only meets production requirements but also enhances efficiency and product quality for our valued customers.

4. Tailored Customization: Recognizing the uniqueness of each customer's needs, we offer comprehensive customization services. Our engineers collaborate closely with clients to develop the most suitable winding machine solutions, ensuring that the equipment's performance and functionality align perfectly with customer expectations.

5. Exemplary After-Sales Support: Prioritizing the post-purchase experience, we provide a comprehensive after-sales support package. From equipment installation and commissioning to training and maintenance, our professional technical team is dedicated to resolving issues promptly, guaranteeing the smooth operation and utilization of our products. Our commitment extends beyond the sale, fostering a lasting partnership with our customers.

Flat Wire Alpha Coil Winding Machine Details

Shenzhen Santong Weiye Technology Co., Ltd. was founded in 2014 in Shenzhen, Guangdong Province, China, which enjoys the title of "Capital of Innovation", and the production factory was moved to Tangxia, Dongguan, from Shenzhen in 2019, the company has a number of technical backbone with more than 15 years of experience in the work of the winding equipment and laser equipment, Shenzhen Santong Weiye Technology Co. Ltd. is a manufacturer of automation equipment and coils integrating R&D, production, sales and service of coil winding machines and flat coils, our flat coil products, vertical coil winding machines and automation equipment have good quality and advantageous price, covering part of the European and U.S. markets. We are looking forward to be your long-term partner in China.

1. 3T-809A flat wire alpha coil winding machine (outer winding machine) is a very practical and effective equipment for making inductance and transformer coils. It can wind flat coils of various shapes and specifications.

2. 3T-809A flat wire alpha coil winding machine (outer winding machine) is simple, convenient and fast for debugging, and only needs to replace the mold;

3. 3T-809A flat wire alpha coil winding machine (outer winding machine) is controlled by computer and driven by servo, which can produce flat wire outer winding products;

4. 3T-809A flat wire alpha coil winding machine (outer winding machine) can be used to debug products of different specifications only by replacing the mold;

5. Multi-station motion, flat coils can be formed and picked up directly on the machine.

6. The windos operation interface and 10 inch LCD display are adopted, with clear and intuitive picture, simple operation and easy learning;

7. It can save the parameters of each specification product, and it is easy and convenient to call.

8. The power system is a high-precision servo motor, which is matched with the CNC control system to make the mechanical system operate more accurately and stably;

Flat Wire Alpha Coil Winding Machine Parameter

|

serial number |

sports event |

Technical Parameters |

|

1 |

Wire Diameter |

0.05mm~0.5mm thick flat wire 0.5mm-5.5mm wide flat line Coil outer diameter: MaxØ 50mm winding amplitude: Max 20mm |

|

2 |

Winding direction |

Outside the two pins winding (clockwise & counterclockwise) |

|

3 |

Maximum working stroke of the row of wires |

50mm |

|

4 |

Power of bobbin winding motor |

AC servo 1600W |

|

5 |

Feeding spool travel range |

1200mm |

|

6 |

Coil fixing method |

Hot air self-adhesive |

|

7 |

Number of control axes |

4-axis |

|

8 |

Number of coils |

1-100 laps |

|

9 |

Winding speed (output per hour) |

200-900PCS/H will be different according to different wire specifications and turns |

|

10 |

Operating power |

AC 380V |

|

11 |

Machine specification (L*W*H) |

1000*550*1600mm |

|

12 |

Machine weight |

200kg |

|

13 |

total power |

3KW |